Templeborough Biomass Power Plant

We generated our first renewable electricity at the plant during July 2018, it now generates around 41MW of green electricity which is enough to supply 78,000 homes and save over 150,000 tons of CO2 every year. It’s difficult to visualise how much that is but would look the same as 250,000 gigantic hot air balloons and the saving is equal to 1.75 million plane flights to Paris.

Generating

of green electricity

Supplying

homes with energy

Saving over

tons of CO2 a year

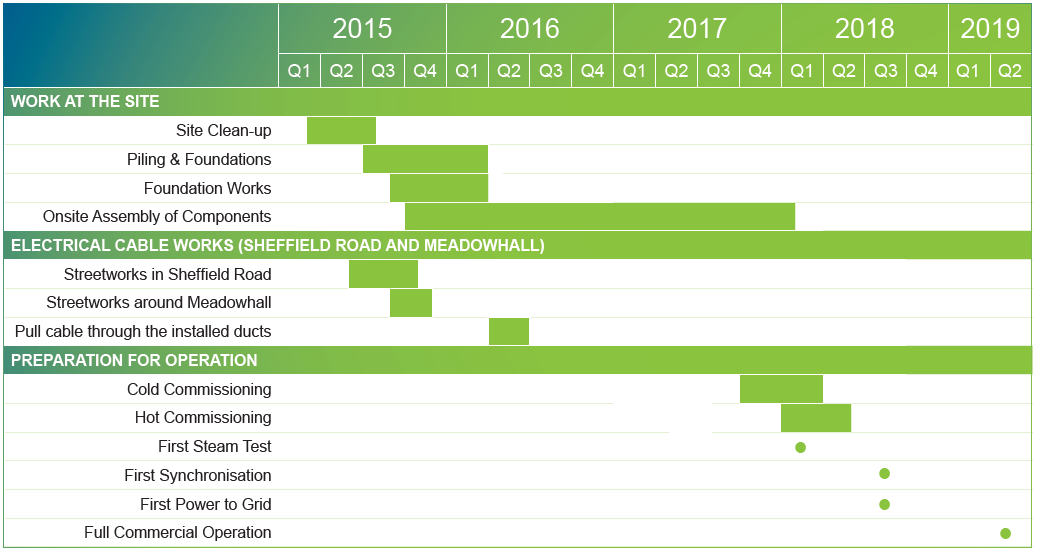

Construction programme

Construction on the brownfield site started on 15th March 2015. The plant first burned wood in May 2018 and first generated clean, green electricity in July 2018. Here’s how we did it:

- We cleared the site, demolishing and crushing over 3,000m3 of concrete and remediating 30,000m3 of earth weighing around 55,000 tonnes, recycling and reusing as much as we could.

- We then began constructing the foundations including piles that go up to 7m underground.

- We built a new bridge over the river which was lifted into place in one piece.

- To construct the boiler, turbine and buildings we had to lift over 2,000 Tonnes steel into place.

- We built a fish pass and an eel pass to encourage native species back along the River Don, creating a swim way from the sea to the traditional salmon spawning grounds in the Peak District

- The first cold commissioning tests took place in November 2017.

- We burned our first wood in May 2018.

- We generated our first electricity in July 2018.

- The Construction team handed the new operating plant over to the operations team in February 2019.

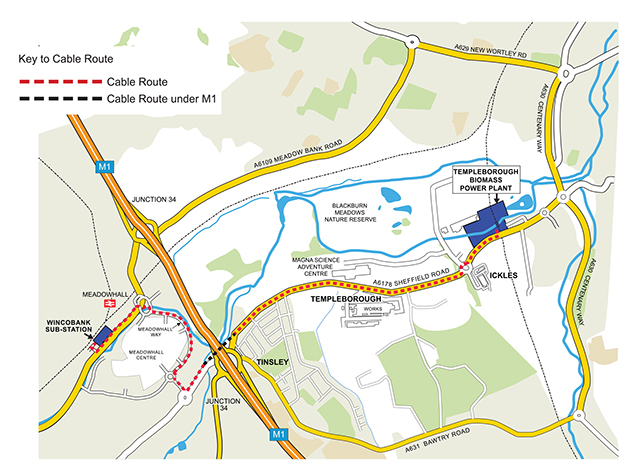

Cable route

The route we are taking is approximately 2.8 miles long, leaving our site and joining the A6178 Sheffield Road at Ickles, it then travels westwards along Sheffield Road through Templeborough, past the Tata Steel works and the Magna Centre. It passes under the M1 Motorway, in a service duct, at Junction 34 (South) and continues along the A6178 before turning north westwards along Vulcan Road to join Meadowhall Way. The cable heads around Meadowhall Way running northwards, eventually crossing the River Don and then travelling south-westerly along Meadowhall Road, the A6109, to join the Northern Power Grid electricity substation at Wincobank.

Bridge lift over the River Don

The Templeborough Biomass Power Plant project continues to make great progress, not only has the skyline changed with the construction of the power plant, but now a new bridge has been installed across the River Don at the site.

Over the Bank holiday weekend of Saturday 28th to Monday 30th May 2016 the old bridge on the site of the Templeborough Biomass plant was lifted out and a new bridge was craned into position. The new bridge was lifted in as a single piece and weighs a mighty 153 tonnes and is over 49m long. The bridge had been assembled at the site during May by Reid Steel from Christchurch in Dorset. The ‘Big lift’ took place overnight on 28th May with the old bridge being lifted out and transported away, the crane used for this lift was a Liebherr LG1750 and has a maximum height of 136m, there are only four of these in the UK. Click here to read the Press Release

How much of the plant will be made locally?

Our power plant is made from many different parts which have to be sourced from companies who specialise in the manufacture of such state-of-the-art equipment. After a lengthy procurement exercise involving companies all over the world, 100% of the project will be manufactured and built by EU based companies. Furthermore, British firms are well represented on the supplier list. With only 12 months of our 28-month build completed, the region around South Yorkshire is already fairing really well among this international competition and many local companies are working with us on site, here are just a few:

• Bulk Excavation and Remediation – Braithwaite’s from Barnsley

• Site Investigations & Dewatering – ESG from Doncaster

• Piling – Simplex from Lancashire (Concrete & Bulk Earthworks sub-supply – Rotherham & Sheffield)

• Groundworks – Moortown from Bradford

• Cranes and heavy lifts – Ainscough from Sheffield

• Steel Frame Structures – Elland Steel from Halifax

• Cladding & Roofing – Barrier Architectural from Retford

• Water Tanks – Plasticon from Hull

• Building Services – Interserve Engineering Services from Leeds

• High Voltage Connection Cable – Interserve Industrial Services (Power) from Wakefield

Altogether, these teams will employ 150-200 people during the construction programme and this list will be added to as the project progresses. All of which goes to show that even though this is a global project sourcing from where the best equipment and the best skills can be found, buying British is still the natural choice for a significant proportion of the project and local companies are a significant part of the story. In fact, to date the project has committed over £40m to the local supply chain and has bought British for over £65m of its budget.

See how we built our power plant

A high speed view from our time lapse cameras, during the main construction phase of the project.

Health and Safety

At Templeborough Biomass Power Plant, we and our contractors embrace the responsibility of creating a safe working environment. All our Contractor’s lead managers have signed the Templeborough Safety Pledge:

“This is our project and we believe that each person working on it deserves to come home from work every evening unharmed and together we share the commitment to make that happen by maintaining a safe site and looking out for each other’s safety”.

Callidus Health and Safety is the Principal Designer for the project operating under the new UK Construction Design Management (CDM) regulations 2015. Throughout this process we will work closely with the Health and Safety Executive to make sure our project and all our team achieve the highest possible Health and Safety standards. For more information please take a look at www.hse.gov.uk/eet/ which provides a brief overview of HSE’s regulatory approach and the challenges faced by renewable energy industries.

Planning and Consents

The project in its current configuration was granted planning permission on the 28 April 2014 by Rotherham Metropolitan Borough Council following consultation with the public and local stakeholders. The Environmental Permit was awarded by the Environment Agency on the 18 July 2014.

The links below provide details of the initial consent granted in 2010 and the amended consent granted in April 2014. There have been further minor changes, discharge of conditions and non material amendments granted since April 2014 – please contact us for a full list.

Planning ref: RB2010/0668

Date: 09/11/2010

Construction and operation of a Biomass Energy Development incorporating two associated biomass combined heat and power (CHP) plants, two chimney stacks (30 m and 40 m in height) with a 200,000 tonne per annum wood pellet manufacturing process and associated infrastructure & landscaping works at former Firth Rixson Ickles Works Sheffield Road Templeborough Rotherham for Brite Partnership.

Planning ref: RB2013/1331

Date: 28/04/2014

Installation of a biomass energy development incorporating a 350,000 tpa wood pellet manufacturing process and an associated biomass combined heat & power (CHP) plant at Firth Rixson Ickles Works Sheffield Road Templeborough Rotherham.